국제경영론 International Business

Chapter. Global Production and Supply Chain Management

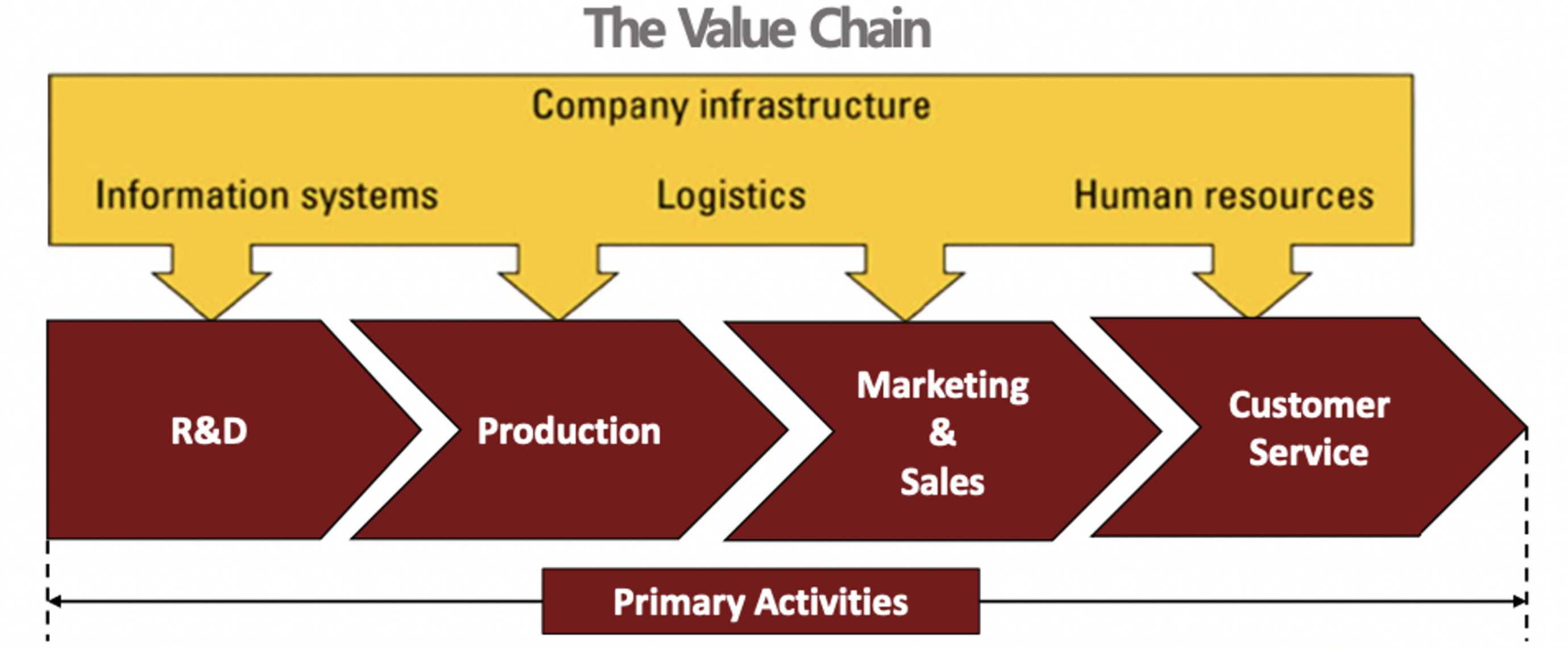

- firms as a value chain

- firms are essentially value chains composed of series of distinct value creation activities, including materials management, human resource, information system, and firm infrastructure

- value creation activities categorized

- primary activity : production, marketing & delivering the product to buyers, and providing support & after-sale service to the buyers

- support activity : help firm to add value

- provide inputs that allow primary activities of production and marketing to occur (information system, communication within the firm, logistic, human resources,, )

- interrelated issues in global economy

- where to locate production activities

- what the long term strategic role of foreign production sites should be

- whether to own or outsource foreign production activities

- how to manage a globally dispersed supply chain and what the role of technology should be in the management of global logistics

- whether to manage global logistics or outsource

Global production : manufacturing activities

생산 시설과 회사를 어디에 위치시킬지

- must consider : (1) country factors, (2) technological factors, (3) production factors

- locating production facility 2가지 전략 존재

- concentrating

- Companies choose one best location for manufacturing.

- They make and ship their products to the world from this place.

- This strategy can save money through large-scale production.

- It also allows companies to control operations tightly.

- The best location is often where costs are low and resources are nearby.

- Factors like skills, transportation, and material access influence this choice

- Decentralizing

- Companies set up many factories in different regions or countries.

- These factories are close to the big markets they serve.

- Being near customers helps companies react quickly to their needs.

- This strategy can cut down on shipping costs and delays.

- It also helps reduce the risk of problems like political trouble.

- Having factories spread out lets companies adjust products for each area's taste or rules.

- concentrating

- country factors : 경제, 정치, 문화, 상대비용적인 조건을 고려 → select most conducive to the performance of activity (stability, cost of input such as labor)

- location externality : Presence of global concentrations of activities (특히, 숙련된 노동자의 능력이나 supporting industries can be key reasons for choosing location

- Regulations affecting FDI and trade barriers : ex. expectations about future exchange rate changes

- transportation cost

- technological factors

- fixed cost : setting up a manufacturing plant are very high → serve the world market from a single location or from a very few locations

- flexibility of technology : Flexible manufacturing technology → wide variety of end products

- Mass customization implies → firm may be able to customize its product range to suit the needs of different customer groups without bearing a cost penalty→ So, firms can act like a local firm without bearing the costs of establishing local manufacturing facilities

- → improve competitive position of firms by allowing the firm to customize products to meet the demands of small customer groups in different markets

- Q. when does it make sense to concentrate production at a few choice locations?

- Concentrated production : fixed costs high, minimum efficient scale of production high,flexible manufacturing technologies are available

- Concentrated not!! : both fixed costs and minimum efficient scale of production are low, flexible manufacturing technologies are not available

- production factors : two product factors impact location decisions

- product’s value-to-weight ratio

- high: a single location and export it ↔ low (like a bottle of water) multiple locations across the world (close to the local market)

- Whether the product serves universal needs→ The need for local responsiveness is reduced for products, which increases the attractiveness of concentrated manufacturing

- (모두가 프로덕트를 같은 방식으로 이용한다면 → u dont need to change it market by market), (국가마다 ,사람마다 다른 방식 이용 → customization 필요)

- product’s value-to-weight ratio

- strategic roles for production facilities

- MNEs used to established and managed foreign plants to benefit only from:

- (1) tariff and trade concessions (2)cheap labor (3) capital subsidies (4) reduced logistics costs.

- Today, MNEs use foreign factories not only to gain access to the usual incentives but also to:(3) create centers of expertise for the entire company (4) global learning!

- (1) get closer to their customers and suppliers (2) attract skilled and talented employees

- Foreign factories can have a number of roles or designations:

- Offshore factory: a factory that is developed and set up mainly for producing component parts or finished goods at a lower cost than producing them at home or in any other market

- Source factory: factory whose primary purpose is also to drive down costs in the global supply chain (expertise o)

- Server factory: factory that is linked into the global supply chain for a global firm to supply specific country or regional markets around the world

- Contributor factory: A factory that serves a specific country or world region

- Outpost factory: A factory that can be viewed as an intelligence–gathering unit

- Lead factory: A factory that is intended to create new processes, products, and technologies that can be used throughout the global firm in all parts of the world

- Q. does strategic rationale for establishing a foreign production facility change?

- The strategic role of foreign factories and the strategic advantage of a particular location can change overtime

- factory initially established to make a standard product to serve a local market, or to take advantage of low-cost inputs, can evolve into a facility with advanced design capabilities

- As governmental regulations change and/or countries upgrade their factors of production, the strategic advantage of a particular location can change

- As the strategic role of a factory is upgraded and a firm develops centers of excellence in different locations worldwide, it supports the development of a transnational strategy

- A focus of a transnational strategy is global learning:the idea that valuable knowledge does not reside just in a firm’s domestic operations, it may also be found in its foreign subsidiaries

- Managers should promote the idea that factories are potential centers of excellence with strategic importance to the firm

- Answer: yes (role of foreign factory change o )

728x90

반응형

'국제경영론IB' 카테고리의 다른 글

| [국제경영론] Global Marketing and R&D (0) | 2024.01.02 |

|---|---|

| [국제경영론] Global Production and Supply Chain Management (2) (0) | 2024.01.01 |

| [국제경영론] Entering foreign markets (2) (1) | 2023.12.31 |

| [국제경영론] Entering foreign markets (1) | 2023.12.30 |

| [국제경영론] The strategy of international business (2) | 2023.12.29 |